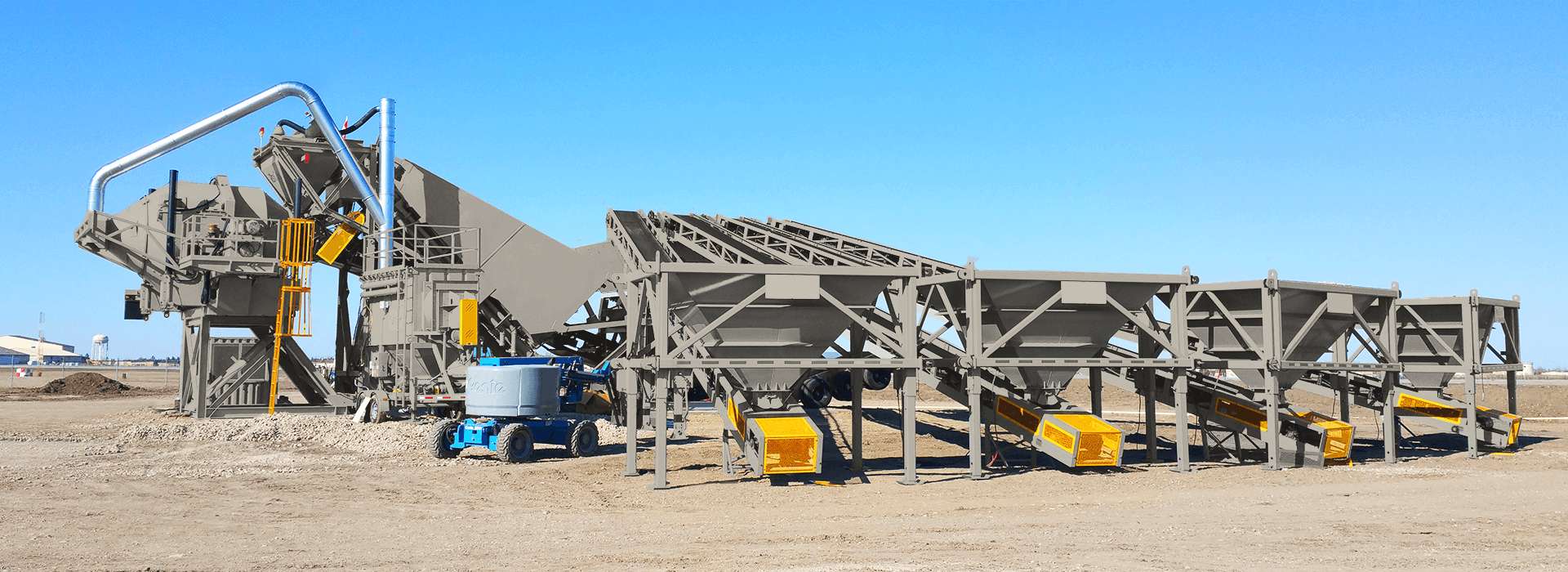

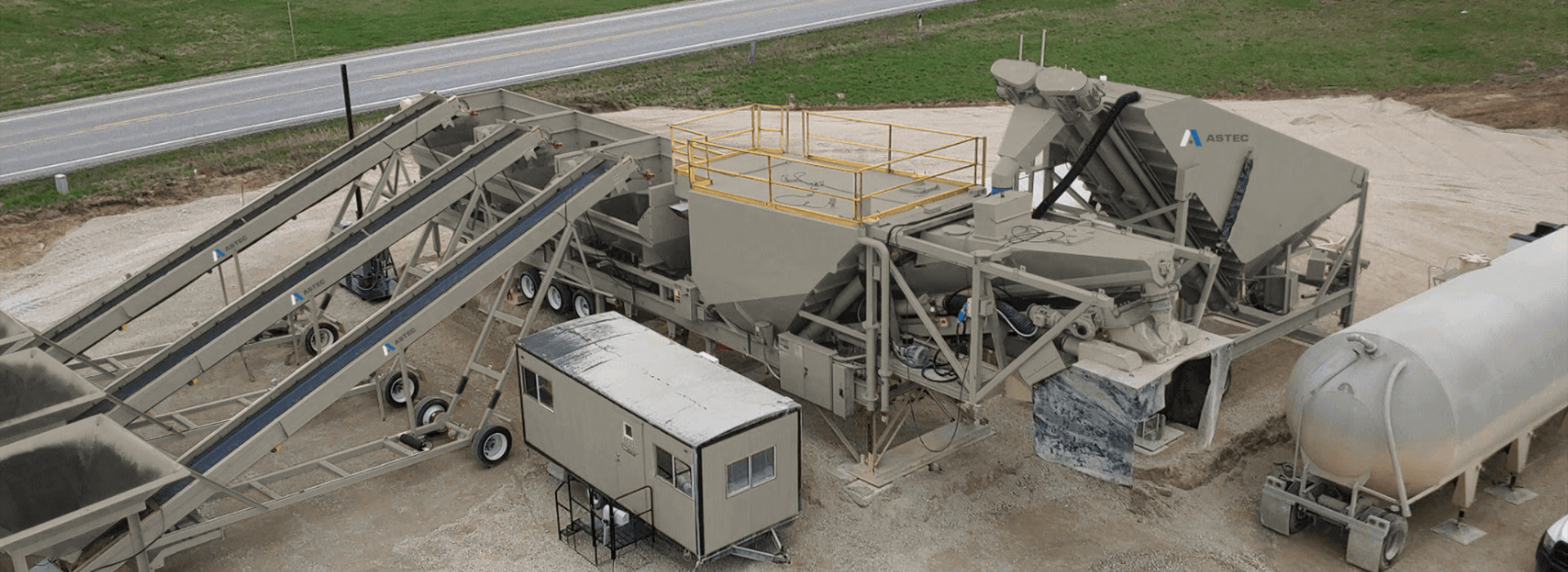

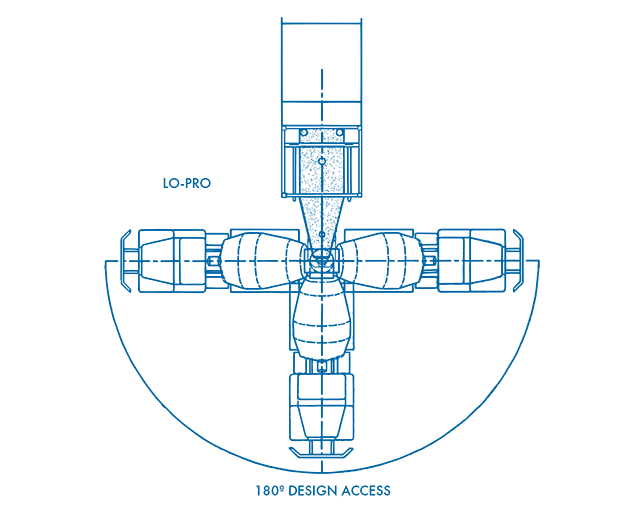

CON-E-CO® LO-PRO Series

Overview

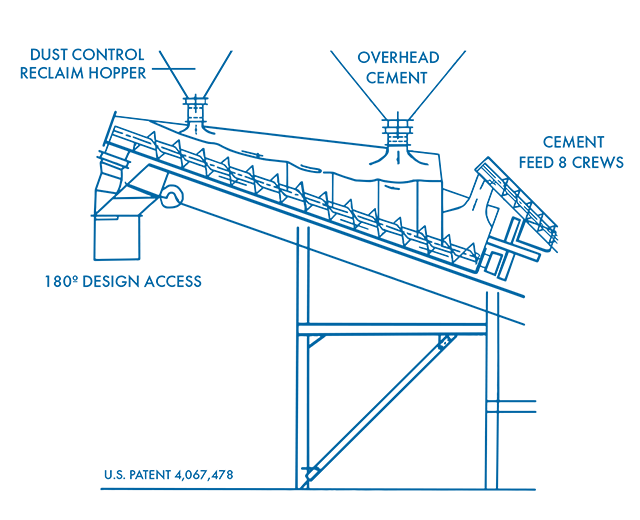

The LO-PRO’S ultra-strong, unitized construction gives this plant tremendous built-in expansion capability!

Dust control systems, unitized cement silos and aggregate storage modules – all may be added to your LO-PRO with simple bolt-on erection. This gives your LO-PRO the ultimate capacity needed for a permanent installation. And the LO-PRO’S compact base size makes it perfect for enclosing where cold weather or environmental restrictions are an issue. When you own a LO-PRO, you will never be stuck with a plant your business has outgrown.

CON-E-CO LO-PRO 327SS

Applications

-

![]()

Road Building - Concrete

Learn MoreAstec's comprehensive line of concrete plants delivers high-quality and durability for the roadbuilding industry with an extensive selection of high-production plants and mixers.

-

![Astec BMH EG Dry Batch Concrete Plant]()

Ready Mix Concrete

Learn MoreMany plants in Astec's extensive concrete product line are well-suited to ready mix operations.

-

![]()

Construction

Construction projects today depend on an available supply of quality concrete mix. With the most comprehensive line of concrete production equipment in the industry, Astec is ready to help meet that demand.Learn More

Downloads

Key Specifications

All specifications subject to change without notice.